|

This being my last week at Georgia Tech I have to create my final embedded circuit, finish my paper, website ,and drive back home this weekend. On Monday I meet with Dr. Zeagler and made a few changes to the circuit design in order for it to be embroidered by the machine. Once it was finished I had to conduct the stress and wash test again to make sure it meets all the requirements, It successfully pass both test and continues to work properly. I was able to finish writing my research paper and to get it reviewed by some close friends and the graduate student I worked with. On Wednesday all the undergrads and Graduate students of Dr. Howard went out to dinner. All in all we all had a great time and where happy we spent the summer together. Finally on Thursday we all went to one of the undergrads SURE presentation and where preparing to leave on Friday.

0 Comments

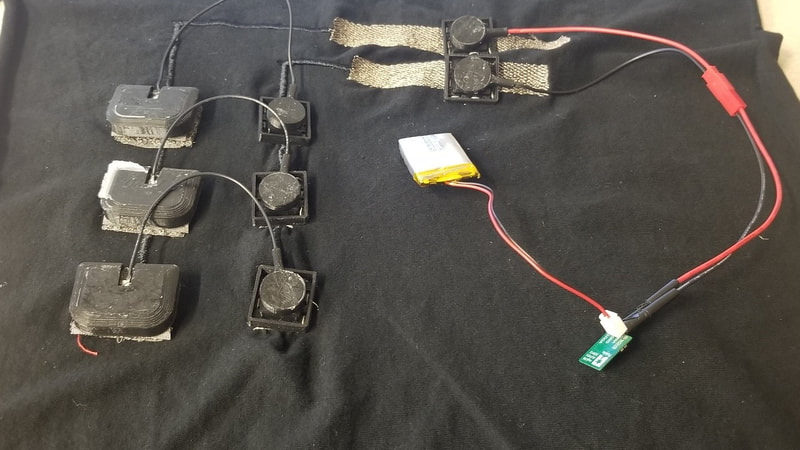

This week we figured out the problem with the sensors that did not work, some of them needed to be updated while the rest had been damaged in the de-soldering process. Now that this problem has been resolved I have enough working sensors to use for the embedded circuit design. We also started making casing for the snap buttons for the snaps connected to the wires and the one's stitched to the fabric. There was a lot of difficulties when creating the casings due to how precise the 3D printer could print the design. Later on in the week I began to build the last circuit needed to complete the testing. I needed to run two test on the circuit before I finished and it was a stress test and a washable test. I was only able to do a stress test due to the fact the week would end soon. On Friday afternoon I was able to get in contact with a professor who has an embroidery machine in his lab specifically for embedded circuits and conductive fabrics. We scheduled a meeting for Monday to build another embedded circuits that would embroider around the traces. Note: the design is a little rough due to the fact that some material was reused for the new suit.

Durring week eight i ran into some trouble with conductivity in the circuit I build last week. Katelyn and I went and test the circuit I made last week to make sure everything is fine before I started building the complete circuit. At the end of the power strip we found that the conductivity was not throughout the whole strip and had to conduct three other circuits to see if it was the glue or conductive thread that lead to it. I found out that the problem was the wire glue, If to much is applied to the strip of conductive fabric it will loose is conductivity completely. No that my problem was solved I Began prepping for the second to last suit test. I began by soldering off all the battery cases attach to the sensors and soldering on all the ground connection wires to the back of the sensors, but when I tried to test them only two out of the five worked. By this time it was Friday and I would have to wait until Monday to figure out the problem.

This week I started building moving forward with the circuit design, by conduction an adhesion test and building the actual circuit. The three glues used for this test where Fray away, Wire glue, and IS glue ( invention Studio) We conducted the adhesion test to see which one has the best properties as far as: insulation, adhesion, conductivity, and durability. there were three different types of glues used. During the first two the fray away glue was the only one to fail. During the conductivity and durability test all of them passed the test. Ultimately the glue I chose to continue working with was the wire glue, because it also kept the fabric from fraying once I started sewing. One other test was preformed to see if the what was the resistance of each material after the glue had been used, and the resistance mainly stayed the same through each material. Lastly I built the embedded circuit on a piece of fabric, and it worked perfectly. Now I can move on to making the complete circuit.

This week I continue to analyze the baby kicking data with the program Ms. Fry had given me. On Tuesday I went to the invention studio again to use the embroidery machine. This week I ran into the following problems with the embroider machine: the needle broke, the embroidery software would not embroider the design correctly, and lastly when the design was transferred the dimension of the design was reduce by 50%. I was not able to figure out the last problem before Thursday( the fourth of July) and had to wait until next week to try to fix the latest problem I have been having.

During the fifth week of the program I began analyzing baby kicking data. The first step in the evaluation process is to take the videos of the baby kicking and split them into 60 sec videos. Once they are split into multiple videos you have to use a program created by Katelyn Fry, the graduate student I am working with. You load the video with the program and click each time the baby is kicking. Once that step is done Ms. Fry take is and runs it through another analysis. Along with that I was finally able to get the supplies I needed to start embroidering. When I began to embroider I ran into a couple of problems and was able to obtain a rough draft of the embedded circuit.

During Week 4 I finished the revisions to the casing and changed its shape back to a more rectangular form. We also decided on the orientation of how the senor was going to sit inside the casing. Before we were going for two different types of orientation so that it would be more user friendly. On e of the improvements I made was to put in blocks in certain locations to help make the senor sit completely flat. This week I also went to the invention studio again to obtain more training on the software and the machine so that the needle would not break next time I went to use it. I am currently waiting on the supplies I need to move forward on the embedded circuit.

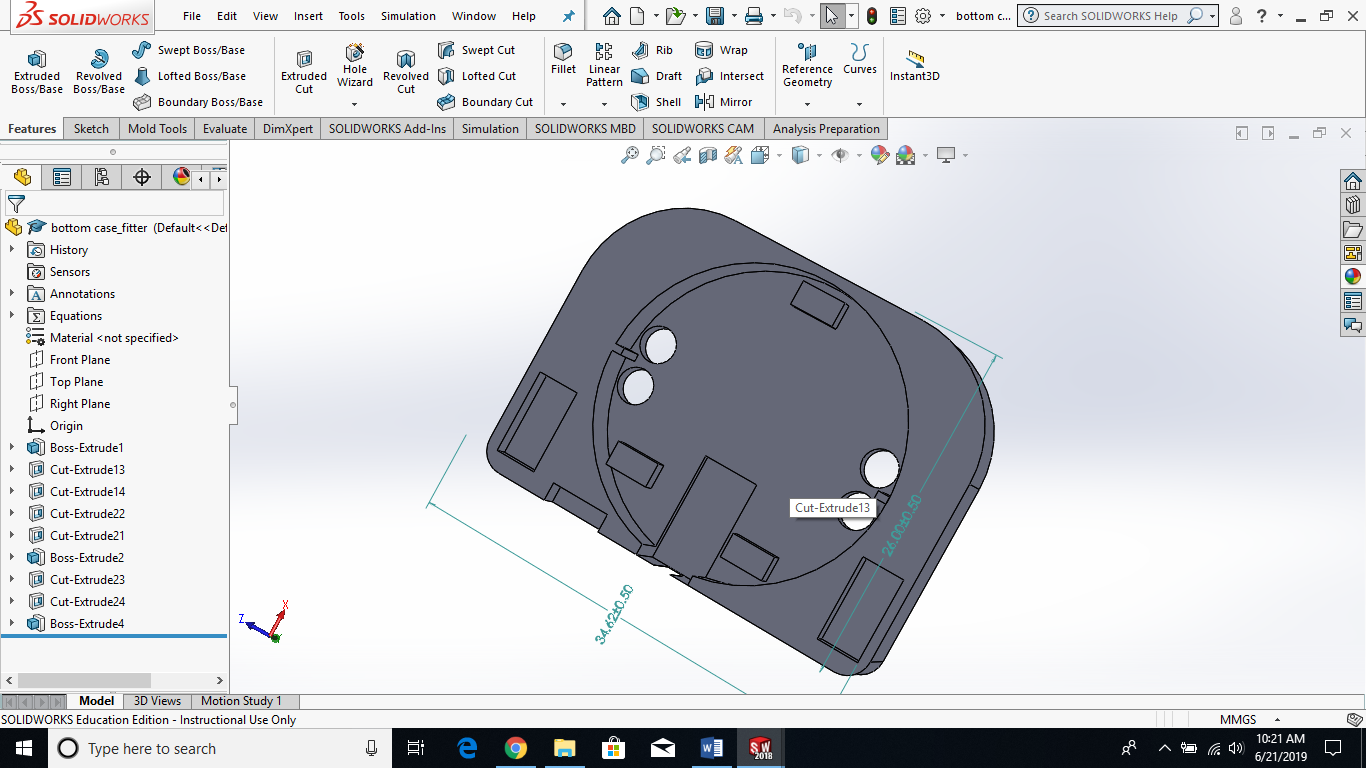

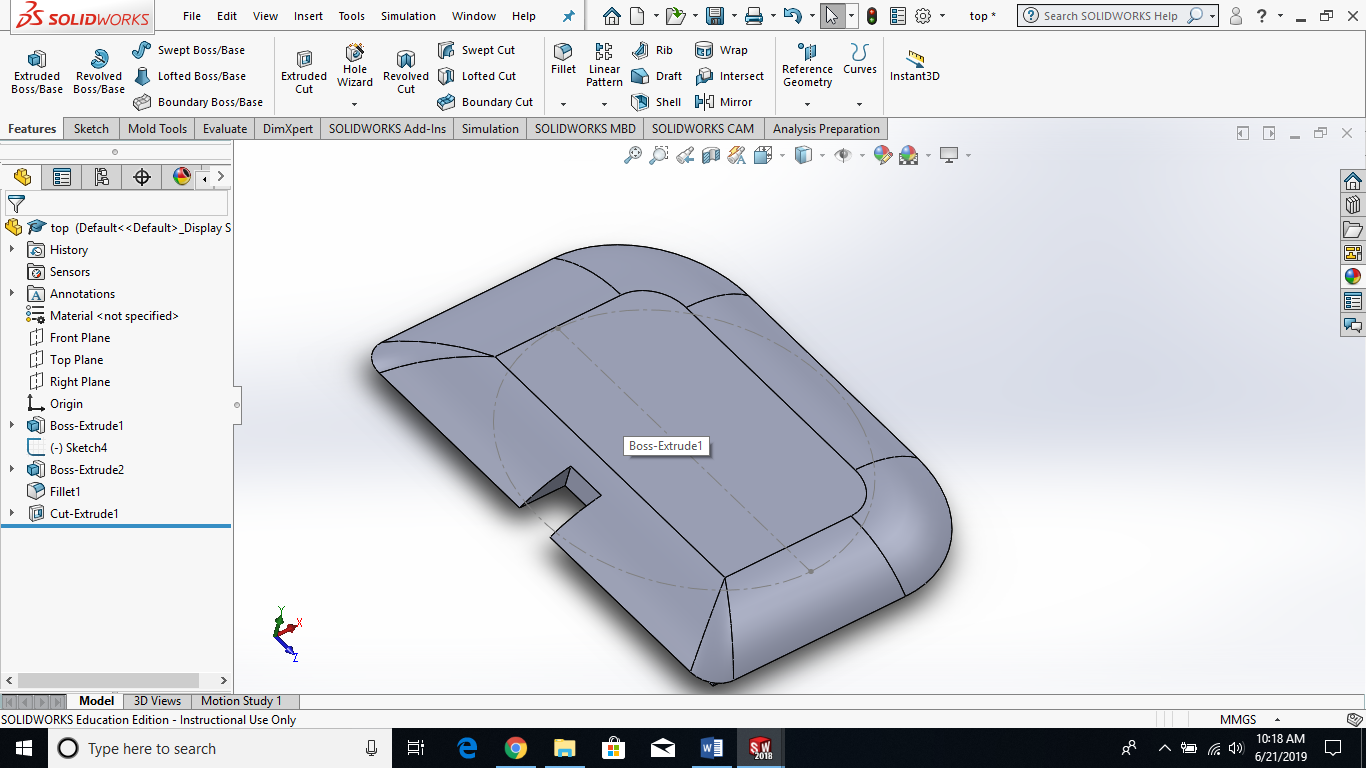

During week 3 I continued working on the 3D casing we had found that their were some errors in the design. One of the major errors in the design was that the sensor did not sit completely flat in the casing and that it was not firmly secure in the casing. I honestly had a little trouble with fixing those errors, because the sensor isn't completely flat itself and different components sit higher than others. Eventually I was able to fix half of the problems by the time the week ended. This week I also went to the invention studio on campus to text out my circuit design and to see if my process for making the needed files would be accepted by the embroidery software. I was able to use the files with the embroider software, but when I went to go test out the file on the embroidery machine the needle broke so I didn't get to how the physical design would come out. I also couldn't go back to run a test again because they also ran out of the necessary materials to make the design. During week 2 I finally designed a casing for the sensor we are going to use to record data. I created the casing using solid-works and the 3D printer in the lab. Creating the casing was somewhat difficult, because I the casing had to have enough space for the the components above and below the circuit and still have the top to snap on and secure the circuit. As you can see the circuit looks a little rough around the edges but hopefully will a bit more refining the rough edges can become smooth. This week I was also able to be trained on the embroidery machine and its software to make the designs. My first week at Georgia Tech was great. It has been truly a graduate school experience. During the program I had to drive back and forth from Georgia Tech everyday. I have had to familiarize myself with Atlanta traffic and choose the right time to leave in order to get to work on time. During the first week of the program I was tasked of coming up with an idea of how to embed a circuit in to baby clothing that would be safe efficient. My other task was to recreate the data collection device used to collect data on spontaneous kicking in solid works.

|

RSS Feed

RSS Feed