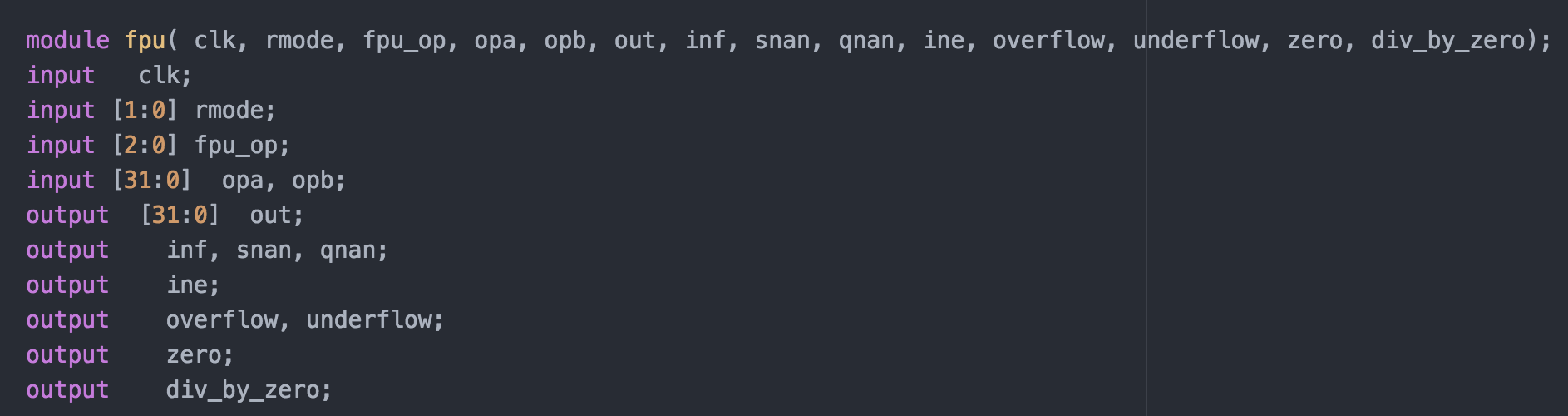

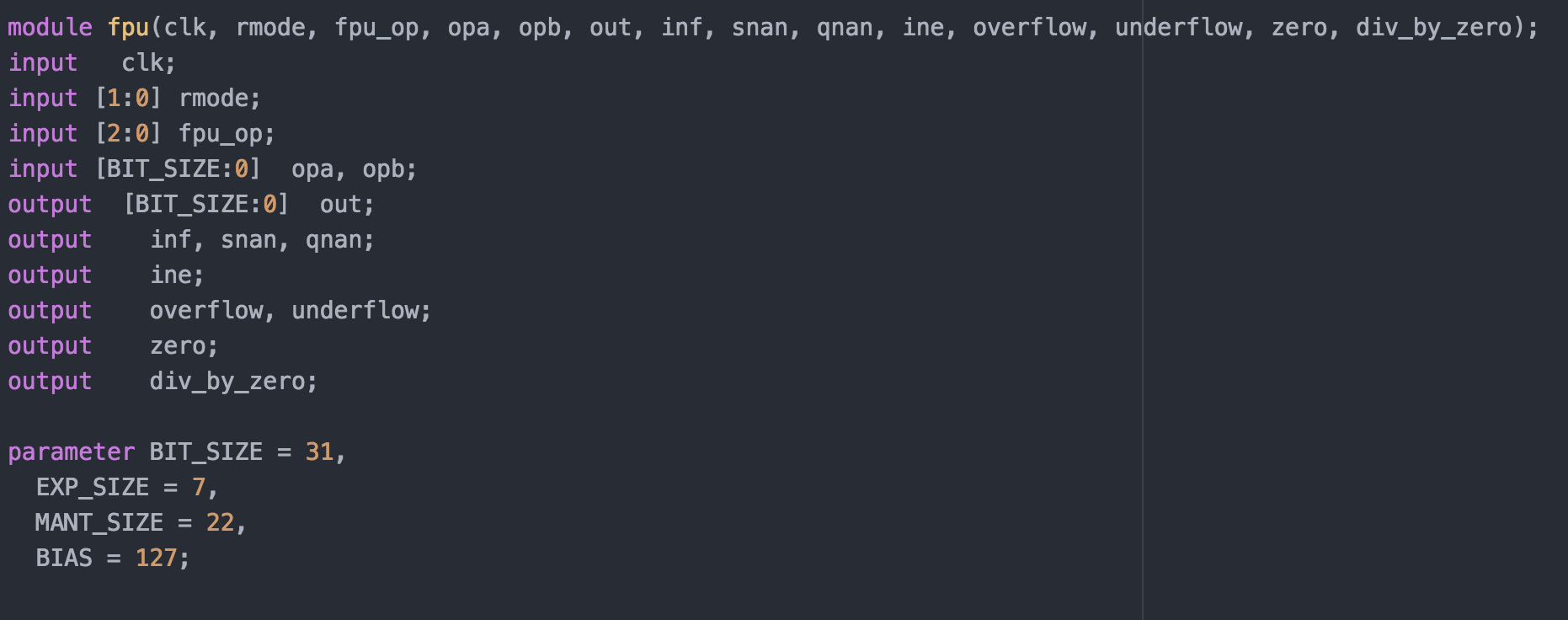

Now that the FPU worked with 32 bit numbers, it needed to be modified to allow for IEEE-754 double precision (64 bits) and IEEE-754 half precision (16 bits). The solution I used was to try and parameterize every line of code that contained hard coded bit lengths.

Before Parmeterization

After Parameterization

After Parameterization

By changing hard coded values throughout the source to parameters, I should be able to affect the input and output precision of the FPU. I spent the rest of the week going through every line of code, testing different values, and modifying the parameters accordingly. Since verilog starts indexing bit arrays at zero, I subtracted one from each of the actual values needed in my parameterization, which made the resulting code a little bit easier to read.